SeeBatch

"seeing is believing"; being seen is motivational

Built from products in TripSaver

With SeeBatch you can keep a watchful eye on your operators 24/7. Under your gaze, every one of them is inspired to be working as effectively as possible, exactly what you need to get the job done well and make perfect process batches. And if circumstances call your operator away from doing the necessary task at the correct time or if the task was done incorrectly you will know precisely what went wrong. Perhaps the operator has too many conflicting tasks to do at the same time; or perhaps the operator was misinformed about how to do a particular task. These are correctable problems that, once remedied, clear the way for perfection. Certainly, under total scrutiny, negligence is not a likely concern.

TripSaver is your way to relaxed, but constant, supervision, while making the work easier for the operator.

TripSaver's footprint - very flexible:

In the TripSaver section, a battery-equipped cart version of the system is displayed. This format is excellent for many applications, especially for a flat area where the cart can be rolled to the site and left to run for hours.

But some locations are very tight or high up and a more compact version, as shown in the photo is preferrable. SeeBatch works with either style.

A key issue in SeeBatch is camera placement. The area for loading the tank and for viewing gauges and meters may be in the same field of view or in multiple ones. Mobility is desirable, but TripSaver also enables the selection of three camera channels, meaning that the operator can leave everything stationary and change views with the click of an icon.

You can view the operator's session in real-time, but the main viewer is ...

the operator!

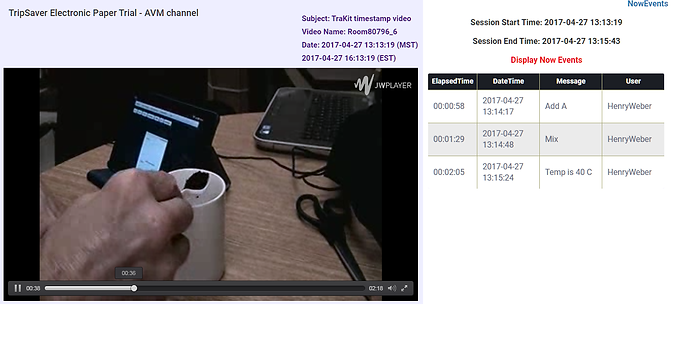

With the TripSaver camera running continuously, the operator uses a tablet to receive the broadcast in order to add NowEvents.

That's all the operator needs to do... just add notes every time something important is done to the process batch.

Click on the image to see a video of a fanciful production setup: a portable TripSaver, a tablet and a cup for making coffee.

To know everything that the operator did to the process batch , you need but go to the location of the NowEvents. The process may last several hours - and the tank is always visible during this time - but to confirm that the tasks were done correctly and on time requires just a few minutes.

Go ahead, try it yourself. Click on the image and watch a "batch of coffee" being made. You would not be mistaken if at first you find it dull. But after realizing that all of the action is labeled and easily found, you might be inclined to change your mind! Just be sure to click on the NowEvent in the upper right of the frame to see the set of operations.